What makes a good sharpening stone?

In an emergency you could sharpen it on any hard rough surface, even concrete. It depends on how hard your steel. The basic principle is, that it should be harder than steel.

Ideally the particles that make up the stone need to break away so that it keeps revealing new clean surface. For example if you sharpen on granite, which does not break off, the steel particles would get clogged in the pores. If you are in nature and have infitinite aupply of new clean granite surfaces, this would be fine. But if the stone is one which you are using in your home for sharpening knives or tools, breaking off is better.

It needs to be densely and uniformly packed. Having uniform small pores is great. As it lets it soak water and make nice slurry. But if the pore size is random it would feel like riding on a potholed road.

I have found sedimentary and metamorphic stones usually suitable for grinding. Sedimentary stones are formed when hard sediment like sand, go under a lot of pressure. It depends on your luck whether the stone that you find has particles of similar size. In case it has fairly big particles mixed with very fine particles, it would act like an emery paper which is 40 or 60 grit but also 800 or 1000 grit. So you would effectively get a 40 grit result, since the biggest particles would make the most prominent impression. I will write another post on basic sharpening where I can elaborate on this.

Where to find it?

I love hunting for these in riverbeds which are full of pebbles. Especially spots where more than one river or stream meet each other. The more diverse the type of stones you find in one place the higher the chances of finding a nice sharpening stone. Look for stones which have visual layers. These are giveaways to them being sedimentary or metamorphic. When sedimentary rocks are heated in high temperature and pressure they metamorphise into metamorphic rocks. These stones are usually harder and take time to form slurry.

In an urban context I have discovered a few different places you can find these.

The first is construction sites where stone is being used. Stones nowadays are used for cladding walls or for flooring. In India temples/monuments being restored, commonly use these. While cutting the raw stones into size there is often quiet some wastage. So you could pick up from the waste pile without feeling guilty. If you have even a small piece of the stone, you could also go to the stone market, if you want to purchase. My suggestion is not to tell them about the real purpose for the stone. You could tell them you need a few samples for your construction.

In Indian cities sometimes an area is monopolized by a certain trade. You may have an area in your city which specializes in stone work. The stone could be for construction. Or for making statues and so on. The waste that comes out of these units is first dumped in corner inside their workshop. Once in a while it is taken out to a dumping site. Municipality grabage trucks do not cater to this stuff. If you are lucky you could find this dumpsite. In Ahmedabad it is next to Gota lake. Be carefull when you are there as it may have unstable mounds of piled broken stones. Also snakes/reptiles maybe resting in the cool niches. This is as jungle as it gets within the city, with all its dangers.

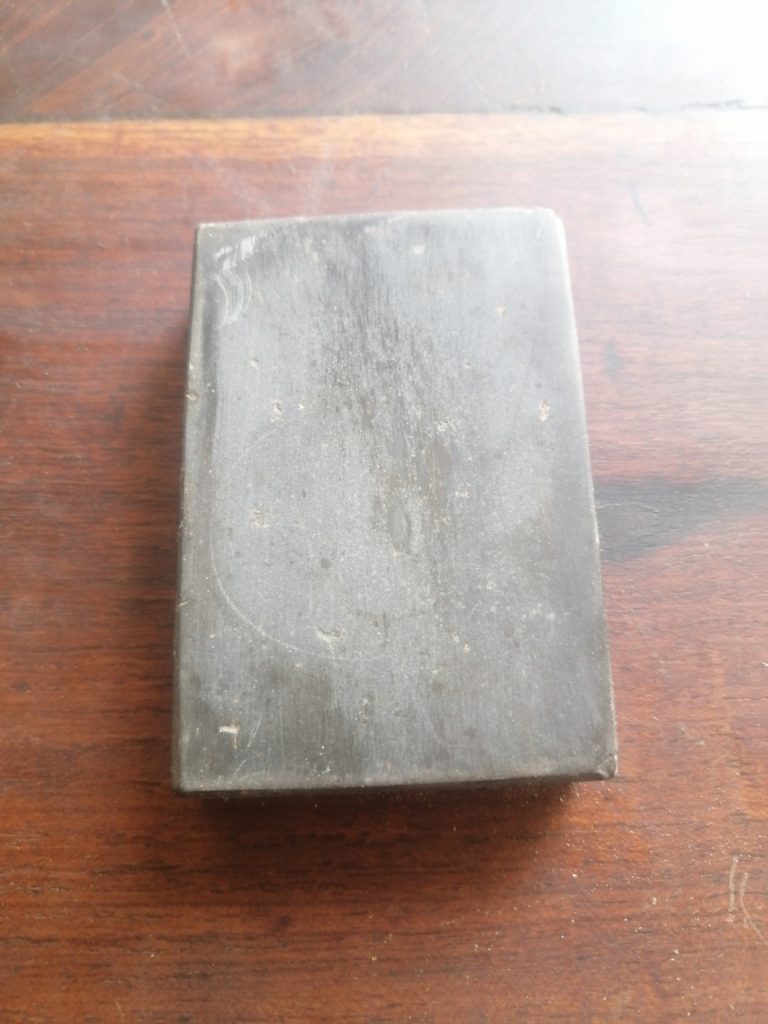

For a really fine grit for polishing to a mirror finish, I have found the gold touchstone (कसौटी पत्थर) to be very suitable. It is available in hardware stores near jewellery hubs. Though it is igneous in nature and doesn’t break off, the uniform small pore size and its incredible bardness make it great for polishing. Once the entire surface gets clogged. You need to remove/file away that top layer to get a new clean surface.